| Connection Machinery |

| Termograffatrice ESS6 | The ESS6 Thermo Crimping Machine has been developed to connect enamelled wires and cables normally used in the electromechanical industry for the construction of electric motors, transformers, coils, etc. The machine combines a high speed cycle with reliability and repetitiveness of the connecting process. The process is based on the use of a clip, produced by the machine itself, as a connection support. Such clip is obtained from a copper strip covered with tin, available in different sections: 0,5x4mm, 0,5x5mm, 0,8x6mm. | |

| Termograffatrice A60 | The new Thermo Connecting System A60 has been developed to connect enamelled wires and cables used in the electromechanical industry for the manufacturing of electric motors, transformers, coils and other. The machine combines a high speed cycle with reliability and repetitiveness of the connecting process. The process is based on the use of a clip, created by the machine itself, as a support for the connection. Such clip is obtained by a copper strip covered with tin, available in different sections. The support can be a simple clip to be used on intermediate connections between wires and cable or it can present the cable lug typical protrusion, to be used as terminal connection. | |

| TermoConnettrice GF10200 | The GF10200 machine has been developed to connect enamelled wires and cables normally used in the electromechanical industry for the construction of electric motors, transformers, coils, etc. The machine combines a high speed cycle with reliability and repetitiveness of the connecting process. The GF10200 machine uses, as a connection support, connectors or cable terminals. | |

| TermoConnettrice GF351000 | The GF351000 machine has been developed to connect enamelled wires and cables normally used in the electromechanical industry for the construction of electric motors, transformers, coils, etc. The machine combines a high speed cycle with reliability and repetitiveness of the connecting process. The GF351000 machine uses, as a connection support, connectors or cable terminals. | |

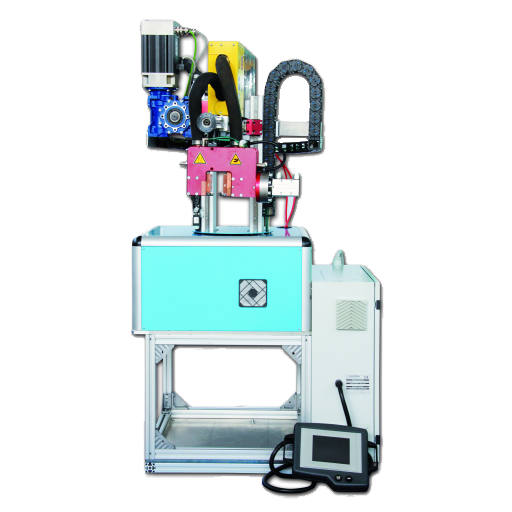

| TermoConnettrice GFA301000 | The machine GFA301000 has been developed to connect enamelled wires and cables normally used in the electromechanical industry following the logical of a semiautomatic process combined to easiness of use, flexibility and high productivity so to get the best consistent and repetitive result. The equipment was designed and built to answer to every specific request coming from “Automotive” field as Tracking and Data Management. | |

| TermoConnettrice GFAA301000 | The GFAA301000 has been designed and built to answer to every specific request of automation on connecting process and on tracking and data management. The GFAA301000 shows its dynamism by the special connection head able to adapt to any single need, ist dimensions can be changed according to available space and stator handling, and the movement happens with a variable number of independent axes (4 to 7) managed by brushless motors and intelligent drivers. This allows to reach the connection point without the presence of an operator, except for a prearrangement station placed close to the machine. | |

| TermoConnettrice GFP301000 | The GFP301000 has been developed to connect enamelled wires and cables following the logics of a semiautomatic process combined to easiness of use, flexibility and high production capacity. It is especially intended for use where the stators’ handling is difficult or where dimensions or weight prevent their movement. The GFP301000 is placed on a trolley that allows its movement close to the stator and it is equipped with a special thermalconnecting head mounted on a two axes assembly.The thermalconnecting head can easily reach the connection area thanks to excursion of about 700mm on the vertical axis and about 900mm on the horizontal axis and can rotate manually of about 225° on the vertical axis. The up/down and left/right movement of axes are each motorized and controlled by a joystick while all the other movements are manual. Besides, it is possible to install the thermalconnecting head in vertical or horizontal position with a lateral tilt of about +/- 15°. |